HDPE

“Aging resistance can be enhanced by adding antioxidants and UV stabilizers to the resin.”

Basic Properties

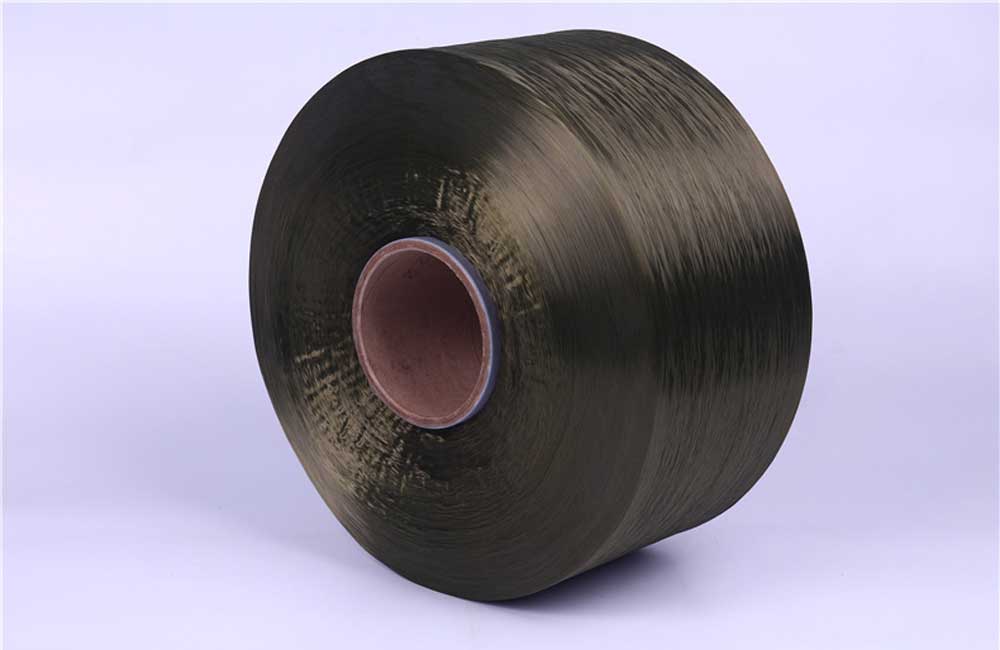

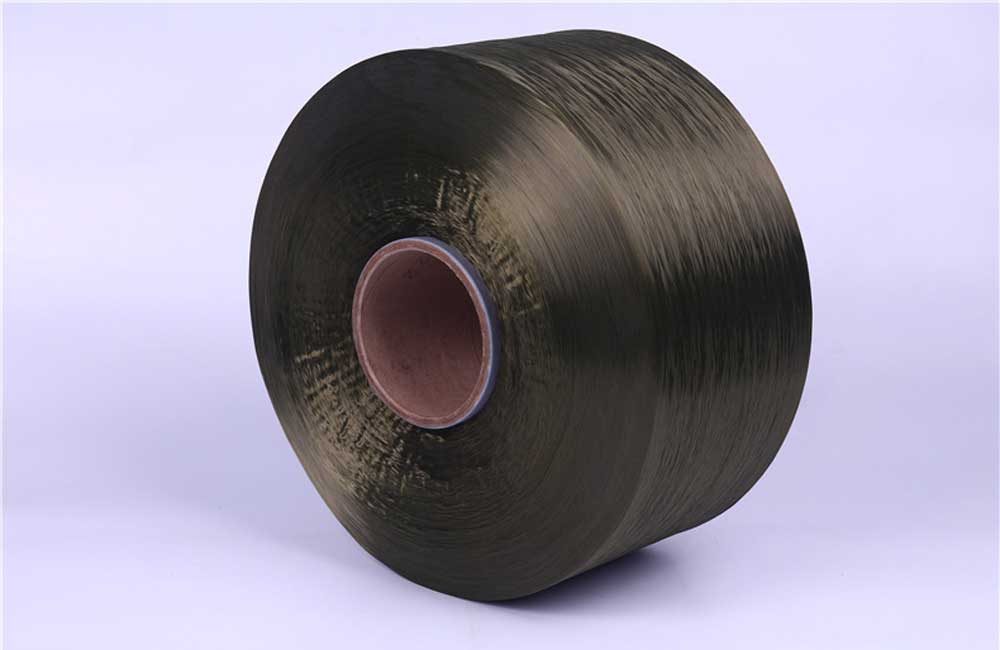

High-density polyethylene (HDPE) raw material is an opaque white waxy material, lighter than water, specific gravity of 0.941 ~ 0.960, soft and tough, elongation, non-toxic, tasteless. Melting point is 142℃, decomposition temperature is 300℃.

Flammable, can continue to burn after leaving the fire, the upper end of the flame is yellow, the lower end is blue, will melt when burning, there are liquid drops, no black smoke, at the same time, emitting the smell of paraffin burning.

High-density polyethylene (HDPE) is an environmentally friendly material, heated to the melting point, can be recycled.

High-density polyethylene (HDPE) is resistant to acid and alkali, organic solvents, excellent electrical insulation, low temperature, can still maintain a certain degree of toughness. Surface hardness, tensile strength, rigidity and other mechanical strength are very high.

High-density polyethylene (HDPE) is used in a wide range of applications, with uses including thin-walled packaging for household goods and food; tough, durable food and paint cans; and high resistance to environmental stress cracking for applications such as small engine fuel tanks and garbage cans. It is used for extrusion of packaging films, ropes, woven bags, fishing nets, and water pipes; injection molding of low-grade everyday products and enclosures, non-load-bearing components, rubber boxes, and crates; and extrusion of blow-molded containers, hollow products, and bottles.

Our 8″, 12″ and 18″ silt sock are made of High-density polyethylene (HDPE), and 5″ is made of Polyester.